CNC milling is a process which cuts the surface of a workpiece with a tool that moves across the workpiece guided by programming. In order for you to get your latest project off the ground, this article will help you learn about some of the basics of CNC milling and what you can expect from it when ordering from a machine shop.

What is CNC Milling?

CNC milling is a type of custom cutting that uses computer-controlled machines to create parts from a variety of materials. CNC milling can be used to create parts for a variety of applications, including furniture, medical equipment, electronics, and more.

There are a few things you need before starting cnc milling. First, you’ll need a computer with a CAD software program installed. Then, you’ll need the appropriate tooling for the job at hand. This can include rotary tools, laser cutters, and other cutting devices. Lastly, you’ll need access to a CNC milling machine.

Once you have all of the necessary tools and equipment, it’s time to start planning your project. First, take stock of what you want to cnc mill and figure out how many parts you’ll need. Next, sketch out your final designs using CAD software. Once your sketches are complete, it’s time to start designing your parts using the programs listed above.

Once your designs are finalized, it’s time to start creating them in 3D using CAD software or laser cutters. Be sure to use accurate measurements when creating your parts; cnc mills require precision in order to produce high-quality results. Once your parts are created, it’s time to transfer them onto the CNC milling machine for manufacturing!

How does a CNC Mill Work?

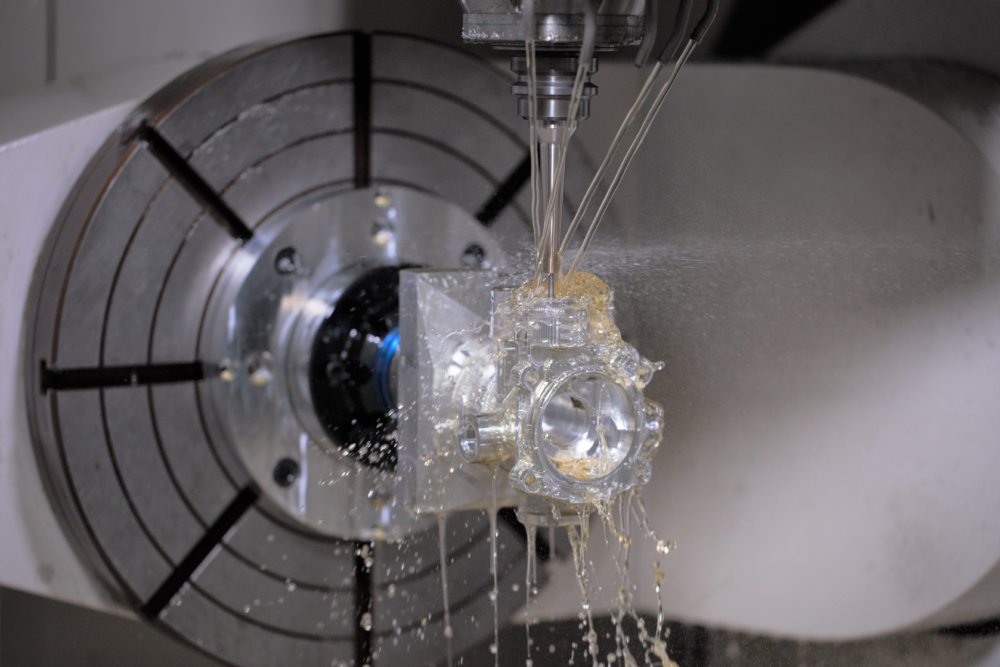

Custom cnc milling is a machine that uses computer-controlled movements to cut or shape materials. The process begins with the use of a computer-aided design (CAD) program to create a drawing or model of the part being milled. This model is then transferred onto the machine’s workpiece table where the actual cutting or shaping can take place.

Since CNC mills are so precise, they can be used to produce a wide variety of products, from jewelry to car parts. In addition, since they’re relatively easy to operate, even beginners can get started using a CNC mill without any difficulty. If you’re interested in starting up your own custom milling business, here are some tips for getting started:

1. Choose the Right Machine

There are many different types of CNC mills on the market, and it can be hard to decide which one is right for you. Some features that you might want to consider include: horsepower, size, and price. Once you’ve determined these factors, you can begin browsing through different models until you find one that fits your needs perfectly.

2. Get a Custom Software Program

Once you’ve chosen your machine and selected the appropriate software program, you’ll need to design your parts using this software. This process involves creating a CAD model of your part and importing this into the software program. Afterward, you’ll need to set up various parameters, such as toolpaths and speeds. It

Advantages of Renewable Energy

Renewable energy is becoming more and more popular as a form of electricity generation. There are many advantages to using renewable energy, including the following:

1. Renewable energy is environmentally friendly.

2. Renewable energy is reliable.

3. Renewable energy is affordable.

4. Renewable energy is sustainable.

5 Tips For Custom CNC Milling (Custom Cutting Machines)

If you’re looking to get into the world of custom milling, there are a few things you’ll need to take into account. This guide will outline some tips on how to get started with your own custom CNC machine.

First, you’ll need to decide what type of machine you want. There are a few options available, including a stationary cnc mill, a turret cnc mill, and a CNC lathe. Each has its own advantages and disadvantages.

Stationary machines are the simplest option and can be used for basic tasks like cutting shapes out of wood or plastic. They’re also relatively cheap, making them good choices if you’re just starting out.

Turret cnc mills are better suited for more complex tasks like creating knock-offs of popular products. They have multiple axes that can move in different directions, allowing for detailed cuts. However, they’re more expensive than stationary machines and require more space to operate.

CNC lathes are perfect for smaller projects that don’t require too much precision or complexity. They’re also quite affordable, making them an ideal option if you don’t have a lot of money to spend on equipment right off the bat.