If you are looking for a wire splice connector, you should know that there are different types to choose from. These include Tap, Pigtail, Crimp, and Solder. So which type of connector do you want to use for your wiring project?

Soldering

Soldering is the process of joining two or more wires together by forming a bond between the conductors using heated metal. This process is used in a variety of applications, including jewelry, stained glass, cookware and computer repairs.

Although soldering is the most common method for splicing wires, there are other methods that provide a more durable connection. One of the best options for splicing is a heat shrink splice.

This type of splice uses a sleeve made of heat shrink that contracts to form a strong sealing area. It’s a simple and easy way to make a permanent waterproof electrical wire connection.

Another common splice is the butt splice. This is the simplest and fastest way to secure the ends of your wires. Butt splices are great because they are inexpensive and require a little hand tooling. They’re also safer to use.

Crimping is another method for making a wire connection. This type of splice is not as common as the soldering or heat shrink splice, but they are a reliable and strong connection.

Crimping

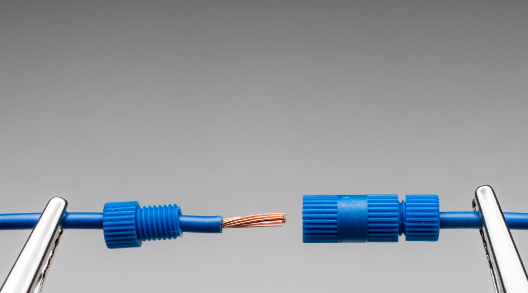

Crimping is a common method of joining wires together. It is a safer, faster, and more convenient alternative to soldering.

Crimping is done with a special tool. First, you will need to place your cable and connector into the tool. Then, you will need to squeeze the handle of the tool. As you squeeze, the tool will compress the wire into the metal portion of the connector. This is the part that seals the connection.

When finished, the crimping process produces an airtight seal between the connector and the cable. Using a crimping tool, you will also be able to repeat the process with additional wire.

Crimp butt splice terminals are tube shaped connectors. They are designed for joining in-line wires to each other. Usually, they are manufactured with an insulated covering.

Crimp butt splices are commonly used in the automotive and boating industries. However, they are also used for several other applications.

Crimp butt splices come in a variety of sizes. The size of the splice depends on the number of wires you need to connect.

Tap connectors

Tap connectors are a great way to make quick and simple connections on your vehicle. You can use them on cars, trucks and motorcycles. They come in a wide variety of sizes and colors to suit your needs. Whether you need to hook up a new accessory or just need to make repairs, a T tap is the answer.

One of the best features of a tap splice is that you don’t have to strip off the insulation from your wire. Depending on the type of connector you choose, this can save a lot of time and frustration.

Another great feature is the ease of use. Some splice connectors require you to crimp the wire. Others may not even require you to use a soldering iron. With a quality T tap connector, your wire will be securely locked into place.

The T-tap has a grooved slot on one side and a flat edge on the other. This allows you to cut through one end of your wire, then plug the second wire into the flat edge.

Pigtail splices

Pigtail splices are a common electrical wiring technique. These splices are used to join wires together in a junction box. They are available in various styles and sizes. The splices can be used to connect two or more wires, or to extend short circuit wires.

To make a pigtail splice, first find a wire connector that fits the size of the wire. This will ensure a secure connection to the wire. It is also important to find a good brand of plastic electrical tape that will protect the wire.

Once you have found a connector, wrap the wire around it. You can use your fingers or a pair of needle-nose pliers to do this. If the wire is too large, you may need to twist it with pliers.

Next, you need to insert the connector in the hole. Depending on the type of wire, you can choose between a Romex connector and a butt connector. Butt connectors are ideal for 12 or 24 volt splicing.