FR4 PCB sheet is a type of a PCB material that has good resistance to moisture and temperature. It is also known for its strength-to-weight ratio, Impedance stability, and Environmental protection.

Thickness

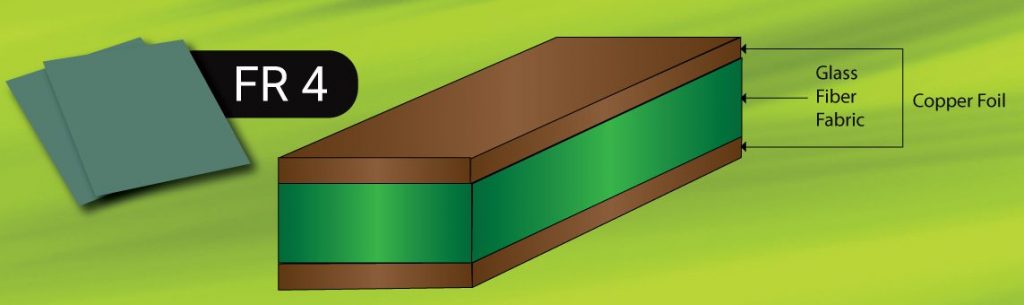

FR4 is a type of laminated epoxy resin that’s used in making rigid circuit boards. It’s a material that’s popular for its versatility and high dielectric strength.

Besides being lightweight and cost-effective, FR4 has many other interesting properties, including being resistant to moisture and fire. It also has a good resistance to weight ratio.

FR4 is usually the default substrate material for quality PCB manufacturing processes. It’s easy to see why. It’s a good choice for many types of electronics applications, and it’s cheap and reliable.

Although a lot of people aren’t aware of FR4, it’s one of the most common circuit board materials. It has many benefits, including being water-resistant and providing circuit integrity. It’s also a good choice for electronic prototyping, especially in dry or humid environments.

Impedance stability

FR4 is a type of glass reinforced epoxy laminate that is widely used as a base material for printed circuit boards. Besides being lightweight and durable, it also offers favorable chemical and environmental properties. Compared to other laminates, FR4 has a very low moisture absorption.

It is the ideal substrate for PCBs in most environmental conditions. However, it also has some disadvantages. While it provides a good balance in electrical stability, it can be susceptible to damage during shipping. In addition, it can be difficult to produce flat amplitude response with frequency.

While FR4 is a good choice for lower frequency circuits, it’s not the best board material for high-frequency applications. The thermal coefficient of a high-frequency laminate is much lower than FR-4.

A high-frequency laminate may be the better choice for circuits that require a controlled impedance. However, it’s not the only material that can meet these requirements.

Moisture and temperature resistance

FR4 PCB material is one of the most popular types of printed circuit boards. It offers a number of benefits, including low cost, moisture resistance, and electrical properties. However, there are also many downsides.

First, FR4 is not a good choice for high-frequency applications. For example, it has a lower dielectric constant than high-frequency laminates. This makes it prone to fluctuating impedance, which can affect the integrity of signal. In addition, it is not a good choice for harsh environments. In fact, FR4 is not suitable for aerospace applications.

In the automotive industry, manufacturers are pushing for more robust temperature-resistance standards. In order to achieve these standards, lead-free soldering is essential. This requires a higher melting point and a higher melting temperature.

Furthermore, it is important to understand how the thickness of FR4 PCB material impacts the performance of the circuit board. Thin boards are more flexible, but they can also be more vulnerable to heat.

Strength-to-weight ratio

FR-4 PCBs offer a high strength-to-weight ratio. This means that FR4 material is very durable and is resistant to moisture and chemical substances. In addition, FR-4 has good thermal and electrical properties.

FR-4 is a commonly used PCB dielectric material. It is made up of an epoxy resin and is woven fiberglass-reinforced sheets. This laminate is commonly used in single-sided or multi-layered boards.

FR-4 has a relatively low cost, which makes it a popular choice for PCBs. Although it is suitable for many applications, it does not meet all requirements. It is also not ideal for high-frequency designs. It does not have a stable impedance, which is important in high-frequency circuits.

Another consideration when choosing a PCB is the operational environment. The temperature, moisture, and humidity of the environment will affect the signal loss and the performance of the PCB.

Environmental protection

FR4 PCB sheet is a high-quality material that is suitable for a number of applications. It has a variety of advantages that include excellent chemical and environmental properties. In addition to providing superior strength to weight ratio, FR4 sheets are also highly resistant to moisture. This makes FR4 a good choice for consumer electronics, marine applications, and high-humidity areas.

Although FR4 is considered the best overall PCB material, there are still many factors to consider when choosing the perfect material for your next project. Some of the more important factors to consider include moisture, temperature, and operational environment. The electrical properties of the material are also important in terms of signal integrity, insulation, and impedance control.

Fortunately, there are many materials on the market that are appropriate for the high-frequency circuits used in modern electronics. For example, Composite Epoxy Materials type three are a strong and affordable alternative to FR-4.