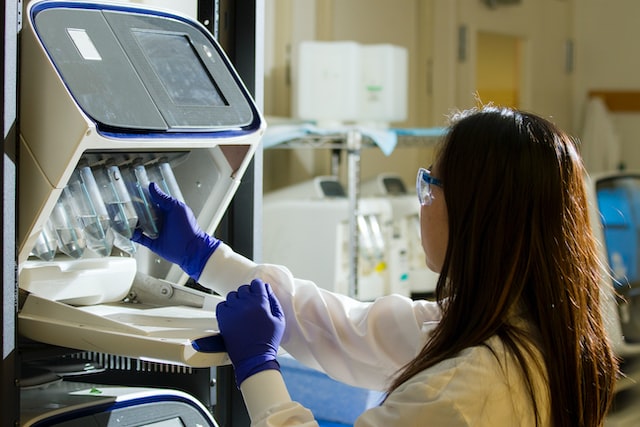

Centrifuges are incredibly useful pieces of laboratory equipment, used in everything from cloning DNA to making artificial blood products. Though some centrifuge models are much larger than others, the basic idea behind them is the same. This article will help you understand how your centrifuge works and how it can benefit you in the lab setting as well as in your everyday life. Click here for more

The basics of how a centrifuge machine works

A centrifuge machine is used to separate different compounds from each other. This can be done by density, which means the denser compound settles to the bottom and the less dense compound stays on top. The separation can also be done by the size or shape of the particle. In a lab, this process is used to separate proteins or other biological molecules. There are two different types of centrifuges: rotary and swing buckets. In a rotary, one half of the container spins while the other remains still. Swing bucket uses swinging arms to spin liquid in all directions at once. Centrifugal force is created when any object moves around a central point. If you were spinning your bicycle tire in circles and then let it go, it would fly outwards away from the center because of the centrifugal force created as it spun around you. When we say that an airplane has taken off and left the ground, what we mean is that the plane has been pushed upwards with enough force so that it could lift off its wheels and leave contact with the ground. When people say they’ve been thrown out of somewhere, like a club, for example, they usually mean they’ve been kicked out forcefully.

The different types of centrifuge machines

Centrifuges are used in research labs and industrial settings to separate solids from liquids. There are three types of centrifuge machines: bench top, vertical, and horizontal. The benchtop type is the most common. It is often found in research labs or hospitals because they take up less space than the other two machines. Centrifuges work by spinning at an extremely fast speed to make the heavier material drop to the bottom of the container while leaving lighter materials at the top. Vertical centrifuges spin on a horizontal axis so that all liquids remain in place during the process. They are best suited for industries that produce large volumes of liquid products.

The advantages of using a centrifuge machine

A centrifuge is an apparatus used to separate mixtures of solid particles or liquids. It can be used in chemistry, biology, medicine, and particle physics. The device consists of a rotating cylindrical drum inside which two immiscible liquids are kept apart by their density or specific gravity. There is always a denser liquid (or one with lower specific gravity) on the outside and the lighter one on the inside. Centrifugal force then causes the heavier liquid to move outward from the center, leaving behind any solid particles that may have been present. Centrifuges are mostly made from glass because it doesn’t react chemically with either fluid. Some metal containers have been successfully used as centrifuges for short periods of time.

The disadvantages of using a centrifuge machine

Centrifuges are the workhorses of the biotechnology industry. They range in size from small benchtop units to large production-scale machines.

But, despite their ubiquity and usefulness, centrifuges have some important disadvantages. The most important disadvantage is that they require very high rotational speeds to be efficient, which can cause vibration. Centrifugal forces generated by the rotating rotor create vibrations at all levels in the system, from the rotor itself to its bearings and support structure. Vibrations will eventually damage the machine and make it less reliable. These problems, coupled with other difficulties inherent in scaling up a manufacturing process, limit the application of large-scale centrifuges to only certain types of products such as purified proteins or DNA segments.

How to choose the right centrifuge machine

Choosing the right centrifuge machine can be difficult. There are many aspects to consider, such as what type of samples you will use it for and how often you plan on using it. However, there is one feature that should always be considered: the rotor speed. The higher the rotor speed, the faster your samples will go through the process and the more effective it will be. If you’re not sure which centrifuge machine would best suit your needs, reach out to us. We would love to talk with you about our equipment and help answer any questions! What types of samples does a centrifuge machine work well for? What size centrifuge machine should I buy?

How do I clean my centrifuge?

Is maintenance required after each use? Most machines require regular cleaning after every 3-5 uses. Be sure to read your machine’s manual for specific instructions and warnings about cleaning chemicals and drying time. What are some of the other considerations when purchasing a centrifuge machine? Do you have some recommendations?