CNC Milling Machine are wont to shape metal, and strong elective materials exploitation specific cutting apparatuses modified and oversaw by pc Numerical administration (CNC) frameworks. The machining technique makes halficular} part or item with the help of CAD programming, short for Computer-Aided Design.

Today, you will not understand a few things that haven’t endured CNC processing machines as most areas trust this particular cycle. A few models are vehicles, planes, machine parts, molds for home machines, toys, and even prosthetics. It is feasible to claim one or numerous CNC machined parts.

CNC Milling Machines And CAD/CAM code

Inside the young people of machining, it was done physically or naturally throughout the long term, the innovation improved and has formed into pc Numerically Controlled frameworks. Presently, with the contribution of a character’s administrator, these PC programs the executives and drive the machining focus. It’s conjointly gone from three and 4-hub to 5-hub precision machining parts to give much more tangled parts.

However, most CNC machine programs use CAD/CAM programming and a programmed cycle; it needs the gifts and experience of a human administrator. they need a goliath job to carry out, including the accompanying:

- Obviously see the {particular}ations

- Started the tooling like this

- Take the cutting circumstances upheld the materials being referred to

- Ensure that the completed item meets the particulars and models

Understanding CNC Milling Machine

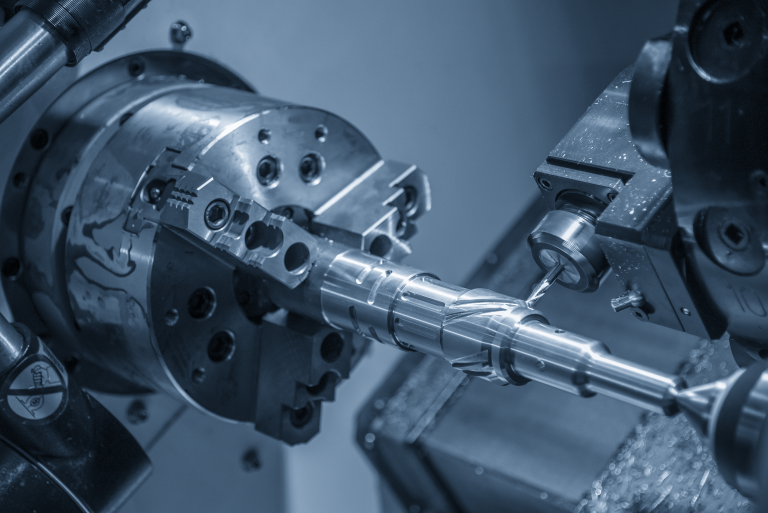

CNC processing machines utilize drills to dispose of materials following bearings from the CAD record to make the particular part or part. The machine’s pc really controls the work and facilitates the shaper and exclusively needs to be stripped of human association to complete the machining system.

Administrators append the work to the table and introduce the cutting instruments on the axle before starting the CNC program. From that point, they’ll begin the CNC Milling Machine and CNC Turning Machine strategy with up to many RPM. When the machine is prepared, administrators could do any of the accompanyings, looking on the undertaking particular:

gradually feed the work into the fixed turning device

get the device across the fixed workpiece

move the apparatus and consequently the workpiece regarding one another now and again

kinds of CNC Milling Machine

CNC processing machines are commonly grouped and upheld how many tomahawks on which they’ll work or the shaft headings. Underneath could be a breakdown of five entirely unexpected sorts:

Vertical Mill

As the name proposes, an upward CNC Milling Machine shaft hub is upward situated. Vertical processing is a philosophy of cutting materials during which the cutting instruments move through the work stays fixed. 2 normal kinds of upright plants are Turret factories and Bed processes, each in activity a touch in an unexpected way.

With a Turret plant, the fixed shaft is upheld by the factory’s table, which can be a hostage in an upward direction or evenly. The post on a Bed plant is situated upward, surrendering and down development. This two-person bike movement of the table and flat travel winds up in the machining activity.

Level Mill

A level factory works similarly to an upward one beside the cutters on a flat shaft. These plants have a greater cross-sectional space than vertical factories, considering quicker material evacuation rates, especially from notches and openings.

3-Axis Mill

The workpieces are secured in situ on the 3-pivot CNC Milling Machine, cnc work near me though the cutting devices execute activities for CNC processing components of different kinds, sizes, and prerequisites.

4-Axis Mill

The design is practically equivalent to the 4-pivot shaper of the 3-hub CNC Milling Machine, except for a turntable, which might do extra tasks.

5-Axis Mill

The 5-pivot processing machines’ movement hub is the Z, which suggests there are 5 headings during which the processing cutters might move, as well as the An and B tomahawks related to the X, Y, and Z straight tomahawks. A 5-pivot machine can follow through with further responsibilities while not resetting the piece or revising the tooling. In any case, more significant levels of exactitude machining need more elevated levels of CAD/CAM programming and an extra complete administrator.

Upkeep Of CNC Milling Machines

Upkeep is moreover a vital feature of an activity CNC processing machines and CNC Machining Components. Administrators should see a method for deciding and resolving potential issues that will emerge through activity. If one thing isn’t working as expected or, on the other hand, if components aren’t being produced true to form, the administrator should see any place to appear and the method for repairing it.

A very much kept up with machine could be useful, and the administrator introductory notification once something isn’t correct. Blames or absence of effects brought about by mileage may be kept away from assuming they’re recognized almost immediately. Accordingly, successful machine upkeep might try and conserve inside the long haul.

A method for trying not to warm during a CNC shop

Warming in a CNC machine shop might wind up in wetness buildup on electronic components, which might bring about erosion. That’s what experts trust; assuming the temperature in a CNC machine shop is high and with moderate dampness, there’s heaps of water around.

CNC machine outlets should board each intensity and dampness level to quit harming gadgets. Though this could be a genuine test, the best arrangements epitomize sufficient air trade, focal air-con, and dehumidifier frameworks. It shouldn’t continually be feasible to keep up ideal temperature and mugginess, but the closer you get, the greater the possibilities of not harming your electronic gadgets.

CNC Milling Machine At PRV Engineering

Throughout the long term, PRV Engineering has stretched our office and activities to fulfill duplicated requests from an always-developing commercial center. Our busy office has very thirty CNC machining focuses with a far-reaching limit. All of our turning habitats have a CAD/CAM interface that grants the U.S.A. to rapidly and with proficiency program the premier high level of parts.

Like turning, all our machining focuses have True 3D-Modeling and an Engraving Facility. This gives us the adaptability to perform a pass on sinking, design making, and etching of particular reason tooling and measures. Reach us assuming you have any inquiries concerning PRV Engineering’s CNC Milling Machine or any way we can work alongside your undertaking. Remember to follow our week-after-week journal posts for every one of the latest improvements in designing, creating, and innovation.