Creality Print is FDM slicing software developed and produced by Creality. It is a China-based company that was found in 2014 to bring 3D printing to the home user market. Since then, they have risen to prominence as a manufacturer of high-quality but low-cost 3D printers, with the Ender series being their best-known and best-selling model.

A creality 3d printer is a new slicer designed specifically for fused deposition modeling (FDM) printers. Since its initial release in January 2022, each update has added compatibility with more machines to reflect Creality’s expanding portfolio. It now supports over 50 machines, including discontinued Creality models like the Ender 2, techcrams which is a nice gesture toward long-time Creality users.

The pros of 3 d creality printer

This manufacturing process has several advantages over traditional manufacturing methods. Among these advantages are those concerning design, time, and cost.

Flexible design – A creality 3d printer allows for more complex designs to be create and print than traditional manufacturing processes. Design restrictions in traditional techniques are no longer applicable with the usage of 3D printing.

Rapid prototyping – 3D printing can create parts in hours, speeding up the prototype process. This allows each step to be finish faster. 3D printing is less expensive and faster at creating parts than machining prototypes because the part can be completed in hours.

Print-on-demand – Another advantage of print-on-demand is that, unlike traditional manufacturing processes, it does not require a large amount of space to stock inventory. This saves space and money because there is no need to print in bulk unless necessary.

Strong and lightweight parts – Although other metals may be utilize, plastic is the most often use 3D printing medium. Plastics, on the other hand, offer an advantage over metal equivalents since they are lighter. This is particularly important in industries such as automotive and aerospace, where lightweight is a concern and can lead to increased fuel efficiency.

Fast design and production -3D printing can create products in hours, considerably quicker than moulded or machined components, depending on the design and complexity of the part. Not only can 3D printing save time during the manufacturing process, but it can also save time during the design phase by producing ready-to-print STL or CAD files.

What Filaments Are Compatible With The Creality Ender-3 3D Printer?

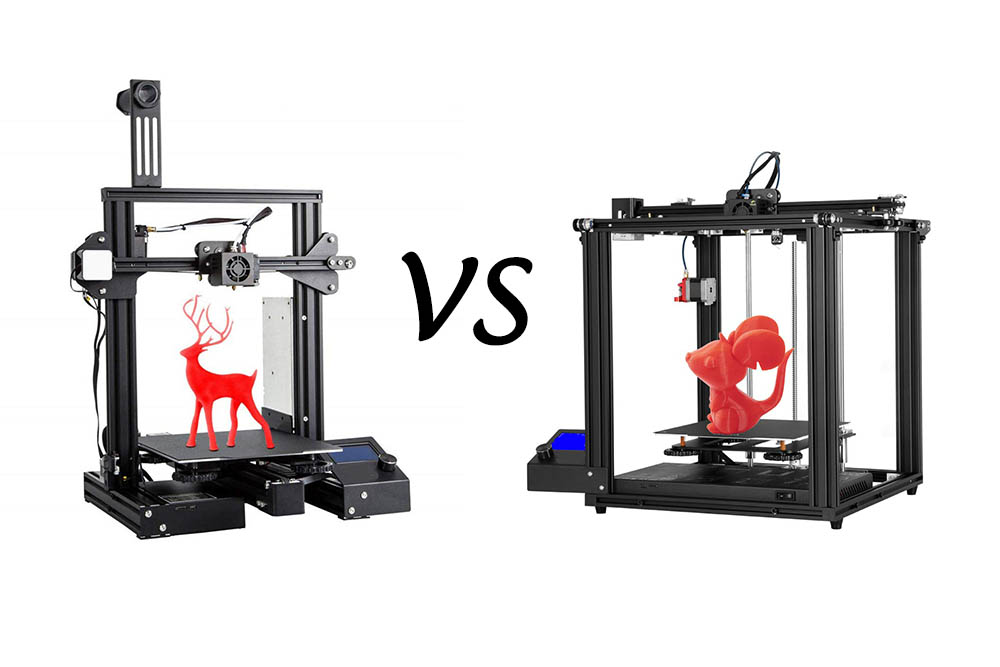

With its dependability and affordability, the Creality Ender-3 3D printer has long been regard as the best choice for 3D printing hobbyists. Since its release, the Creality Ender-3 3D printer has set incredible sales records, with a total annual shipment of 100,000 units. Based on audience feedback, the Creality Ender-3 3D Printer is an exceptional 3D printer when considering the sub-$200 price tag.

Despite being a low-cost 3D printer, the Creality Ender-3 3D printer can outperform many high-end machines on the market. For example, its broad material compatibility will make it more versatile than its competitor machine. Before delving into its filament compatibility and print performance, we would like to learn more about its components, which will influence the performance of various filaments.

Conclusion

The time it takes to 3D print is determine by several factors, including the type of 3D printing technology use, the material used the size of your 3D model, and any post-processing you wish to perform.