In the relentless pursuit of competitive advantage, manufacturing and engineering teams are constantly battling two fronts: cost and quality. The traditional view often pits these two against each other. However, a paradigm shift is underway, led by the capabilities of modern precision machining. This isn’t about finding the cheapest supplier; it’s about leveraging advanced manufacturing technology to design out costs and build in efficiency from the ground up.

For engineers and operations managers on platforms like Techcrams, the question is concrete: How do technical specifications like ±0.0001″ tolerances and Ra 0.4µm surface finishes translate to bottom-line savings? Let’s break down the engineering principles behind the economics.

1. The Myth of Unit Price: Understanding Total Cost of Ownership (TCO)

A common mistake is sourcing based solely on a piece-part price. True cost analysis must consider the Total Cost of Ownership, which includes:

- Inspection and QC Costs: Loosely toleranced parts require 100% inspection, a massive hidden cost.

- Scrap and Rework Rates: Inconsistent parts lead to line stoppages and wasted materials.

- Assembly Labor: Parts that don’t fit perfectly require filing, shimming, and force-fitting, increasing assembly time.

- Warranty and Field Failures: A single part failure in the field can cost thousands of times its purchase price in repair, logistics, and brand damage.

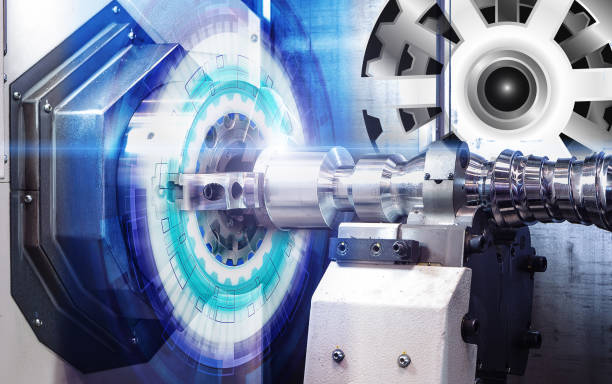

This is where the selection of your precision machining parts manufacturer becomes a strategic decision. A partner like Falcon CNC Swiss employs advanced 5-axis CNC mills and Swiss-type lathes that produce parts with exceptional consistency. This consistency is the first and most critical step in reducing TCO. By delivering parts that are correct every time, they eliminate the downstream costs of variability.

2. Case in Point: Hydraulic Manifolds – Efficiency Through Integration and Precision

Hydraulic systems are the lifeblood of heavy machinery, and their efficiency is paramount. The manifold, which directs fluid flow, is a perfect example of how precision machining creates value.

Inefficient, traditionally manufactured manifolds often use multiple drilled and plugged channels, which can create turbulence, pressure drops, and potential leak points. This leads to energy loss (increased horsepower requirements) and heat generation.

Leading hydraulic manifold manufacturers now utilize sophisticated 3D CNC machining to create complex, internal cross-drilled channels with optimized geometry. This minimizes fluid friction and pressure loss. The result is a direct energy saving for the end-user. Furthermore, the ability to machine multiple ports and mounting features directly into a single block of material—a capability central to Falcon CNC Swiss’s process—eliminates the need for additional fittings, brackets, and seals. This “component consolidation” reduces:

- Part Count: Simplifying Bill of Materials and procurement.

- Assembly Time: Fewer parts to stock, handle, and assemble.

- Potential Failure Points: Every connection removed is a potential leak eliminated.

The precision in the machining process ensures that seal surfaces are flawless, and port alignments are perfect, leading to a leak-free, high-efficiency system from the first installation.

3. The Unseen Strength: How a Precision CNC Machined Bracket Reduces Weight and Assembly Time

Weight and complexity are enemies of efficiency. Nowhere is this more evident than in structural components like brackets. A poorly designed bracket is over-engineered—heavy, bulky, and requiring multiple manufacturing steps.

A precision CNC machined bracket represents the antithesis of this approach. Using techniques like topology optimization and finite element analysis (FEA), engineers can design a bracket that uses the minimal amount of material only where it is structurally needed. A multi-axis CNC machine can then produce this complex, organic-shaped design from a solid block of high-strength aluminum or titanium.

The economic benefits are direct:

- Material Savings: The final part uses significantly less raw material, reducing cost and waste.

- Lightweighting: In automotive and aerospace applications, reducing weight directly translates to better fuel efficiency and payload capacity.

- Design Integration: A single, complex CNC machined bracket can often replace an assembly of several welded or bolted pieces. This was a key challenge we solved at Falcon CNC Swiss for a client in the robotics sector. By replacing a six-piece welded assembly with a single, monolithic 6061 aluminum bracket, the client saw a 40% reduction in part weight, a 60% reduction in assembly labor, and a dramatic increase in structural rigidity and repeatability.

4. The Falcon CNC Swiss Methodology: Engineering Your Profitability

The common thread in these examples is not just the machine, but the methodology. At Falcon CNC Swiss, our approach is rooted in Design for Manufacturability (DFM). We don’t just make prints a reality; we collaborate with engineering teams to refine designs for optimal performance and cost-effectiveness before the first block of material is ever cut.

This involves:

- Material Selection Advice: Guiding clients to the most cost-effective and performant material for their application.

- Tolerance Analysis: Recommending which features require extreme precision and which can be relaxed to save cost without sacrificing function.

- Process Optimization: Selecting the right technology from our arsenal, be it 5-axis milling for complex contours or Swiss machining for tiny, high-volume components.

Conclusion: Precision as a Strategy

In the modern manufacturing landscape, precision machining is far more than a production step. It is a comprehensive strategy for eliminating waste, simplifying assembly, and enhancing product reliability. By focusing on the technical capabilities that drive down the Total Cost of Ownership—from a perfectly machined hydraulic manifold to a structurally optimized bracket—forward-thinking companies can turn their manufacturing process into a source of undeniable competitive advantage.

The goal is to build better, smarter, and more efficiently. And that goal begins with a partnership with a precision machining parts manufacturer that understands the deep, intrinsic connection between microscopic tolerances and macroscopic business success.