The pharmaceutical industry is constantly evolving and seeking new ways to improve the efficiency and accuracy of drug production. One area that has seen significant advancements is in capsule filling. Gone are the days of manually filling capsules one by one; now, with the use of pharmaceutical capsule-filling machines, the process has been revolutionized. These innovative machines are designed to precisely and efficiently fill capsules with a variety of medications, making them an essential piece of equipment for any pharmaceutical company. In this blog post, we will take a closer look at these machines and how they are transforming the capsule-filling process.

Understanding the Core Functionality of Capsule Filling Machines

Pharmaceutical capsule-filling machines are intricate pieces of equipment that play a vital role in the drug manufacturing process. These machines are designed to precisely and efficiently fill capsules with medications, ensuring accurate dosages and consistent quality.

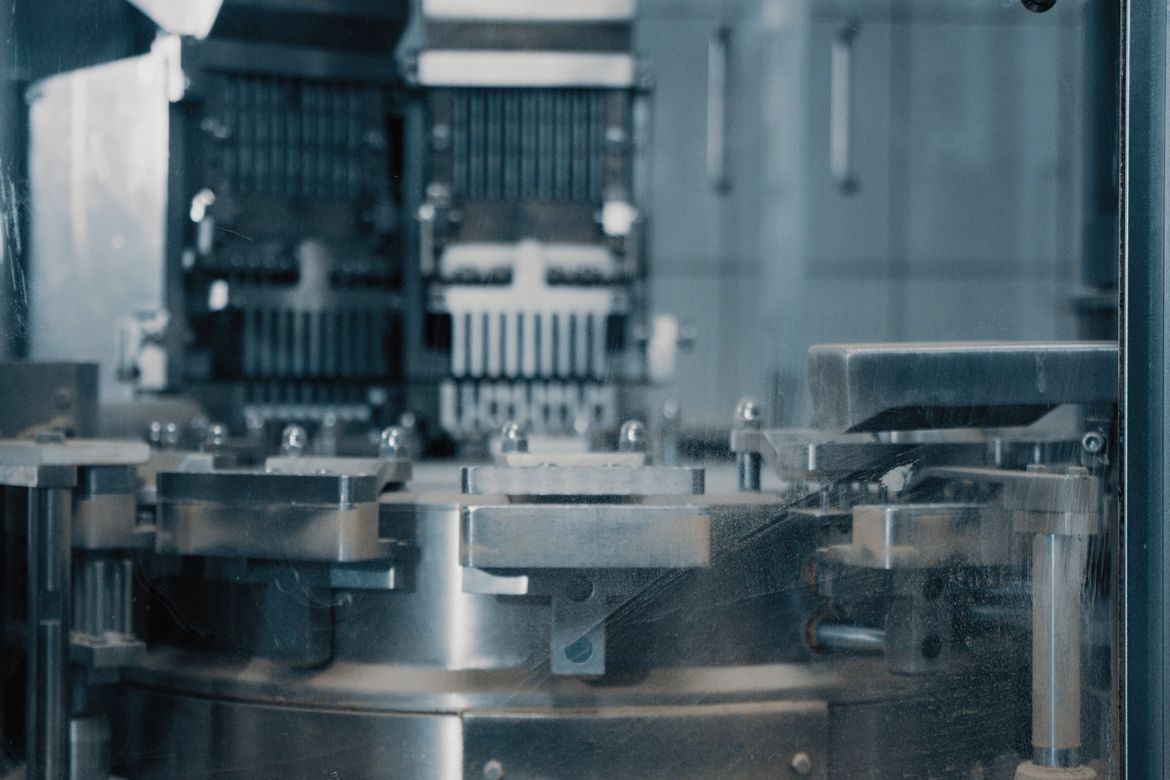

At their core, capsule-filling machines work by first separating empty capsules and filling them with the desired medication or formulation. The machine carefully positions the capsules, fills them with the appropriate amount of medication, and then seals them shut. This entire process is automated and controlled, minimizing the risk of errors and contamination.

To achieve this, capsule-filling machines employ a variety of mechanisms, such as vacuum suction to hold and position the capsules, powder dosing systems to accurately dispense the medication, and mechanical systems to seal the capsules shut. These machines are also equipped with sensors and controls to monitor and adjust various parameters, ensuring precise filling and minimizing waste.

Understanding the core functionality of capsule-filling machines is essential for pharmaceutical companies to maximize productivity, efficiency, and product quality. With a solid foundation of knowledge, companies can select the right machine for their needs and optimize their capsule-filling operations.

Different Types of Capsule Filling Machines and Their Uses

Pharmaceutical capsule filling machines come in various types, each designed to cater to different needs and applications in the industry. One type is the manual capsule-filling machine, which is suitable for small-scale production or when the need for flexibility arises. These machines are typically operated by hand and require the user to fill and close each capsule manually.

Another type is the semi-automatic capsule-filling machine, which combines manual labour with automation. These machines have features like automatic filling and closing, making them suitable for medium-scale production. They provide greater efficiency and accuracy compared to manual machines while still allowing for some level of human control.

For large-scale production, automatic capsule-filling machines are the go-to choice. These machines are fully automated and can handle high volumes of capsules. They offer precise filling, high speed, and minimal human intervention, making them ideal for pharmaceutical companies with large production needs.

Ultimately, the choice of capsule-filling machine depends on the specific requirements and scale of production. By understanding the different types available, pharmaceutical companies can make informed decisions to optimize their capsule-filling processes.

Key Features of Modern Capsule Filling Machines

When it comes to modern capsule-filling machines, several key features set them apart from their predecessors. One of the most important features is accuracy. These machines are designed to fill capsules with precise dosages of medication, ensuring that patients receive the correct amount every time. Additionally, modern capsule-filling machines are equipped with advanced controls and sensors that monitor and adjust various parameters, such as fill weight and capsule position. This not only helps to minimize waste but also ensures that the capsules are sealed shut correctly to prevent contamination. Another key feature is speed. With high-speed mechanisms, these machines can fill hundreds or even thousands of capsules per minute, significantly improving productivity for pharmaceutical companies. Finally, modern capsule-filling machines are often designed with easy-to-clean surfaces and materials, allowing for efficient and hygienic operations. These key features make modern capsule-filling machines a crucial investment for pharmaceutical companies looking to optimize their production processes and maintain high-quality standards.

The Importance of Capsule Filling Machines in the Pharmaceutical Industry

Capsule-filling machines play a crucial role in the pharmaceutical industry, providing a range of benefits that are essential for drug manufacturing. These machines are instrumental in ensuring accurate dosages and consistent quality in the production of medications. By automating the capsule-filling process, these machines greatly reduce the risk of errors and contamination, resulting in safer and more reliable medications for patients.

The importance of capsule-filling machines cannot be overstated. They significantly improve productivity by filling hundreds or even thousands of capsules per minute, enabling pharmaceutical companies to meet high demand. Additionally, the advanced controls and sensors in modern capsule-filling machines help minimize waste and ensure proper sealing, preventing any potential contamination that could compromise the efficacy and safety of the medication.

Overall, capsule-filling machines are a crucial investment for pharmaceutical companies looking to optimize their production processes and maintain high-quality standards. These machines revolutionize the capsule filling process, enhancing efficiency, accuracy, and, ultimately, the well-being of patients who rely on medications every day.

Challenges and Solutions in Capsule Filling Operations

As with any complex process, capsule-filling operations come with their fair share of challenges. One of the main challenges is achieving consistent fill weights. Ensuring that each capsule is filled with the exact dosage of medication is crucial for patient safety and product efficacy. This requires precise control over the filling process and careful calibration of the dosing systems.

Another challenge is the risk of contamination. Capsule-filling machines must be maintained and cleaned regularly to prevent the build-up of residues that could contaminate the medications. This requires thorough cleaning protocols and adherence to strict hygiene practices.

Additionally, capsule-filling machines may encounter issues with capsule alignment and positioning. Improper alignment can result in uneven filling or even the capsules getting stuck in the machine. Addressing these issues requires careful adjustment and calibration of the machine’s positioning mechanisms.

To overcome these challenges, pharmaceutical companies invest in advanced capsule-filling machines that come with innovative solutions. These machines often incorporate advanced sensors and controls that ensure precise dosing, automatic cleaning cycles, and self-adjustment mechanisms for alignment issues. By leveraging these technological advancements, pharmaceutical companies can overcome the challenges associated with capsule-filling operations and ensure the production of safe and high-quality medications.

The Future of Capsule Filling Machines: A Glimpse into Innovations

As technology continues to advance, so does the future of capsule-filling machines. Innovations in this field are focused on improving efficiency, accuracy, and overall productivity. One exciting development is the integration of artificial intelligence (AI) and machine learning (ML) algorithms into capsule-filling machines. These technologies have the potential to optimize dosing precision by analyzing vast amounts of data and making real-time adjustments. By constantly learning and adapting, AI-powered capsule-filling machines can ensure even greater accuracy and consistency in filling capsules.

Another area of innovation is the use of robotics and automation. Robotic capsule-filling systems are being developed to handle the entire capsule-filling process autonomously. These machines can load empty capsules, dispense medication, and seal the capsules shut with minimal human intervention. This not only improves productivity but also reduces the risk of contamination and human error.

Furthermore, advancements in materials and design are making capsule-filling machines more hygienic and easier to clean. Self-cleaning mechanisms and surfaces that resist residue build-up are being incorporated into the machines, ensuring high levels of cleanliness and minimizing the risk of cross-contamination.

In conclusion, the future of capsule-filling machines holds exciting possibilities for the pharmaceutical industry. With AI, robotics, and improved hygiene features, these machines are poised to revolutionize the drug manufacturing process even further. As technology continues to evolve, we can expect to see even greater levels of accuracy, efficiency, and safety in capsule-filling operations, ultimately benefiting both pharmaceutical companies and patients.