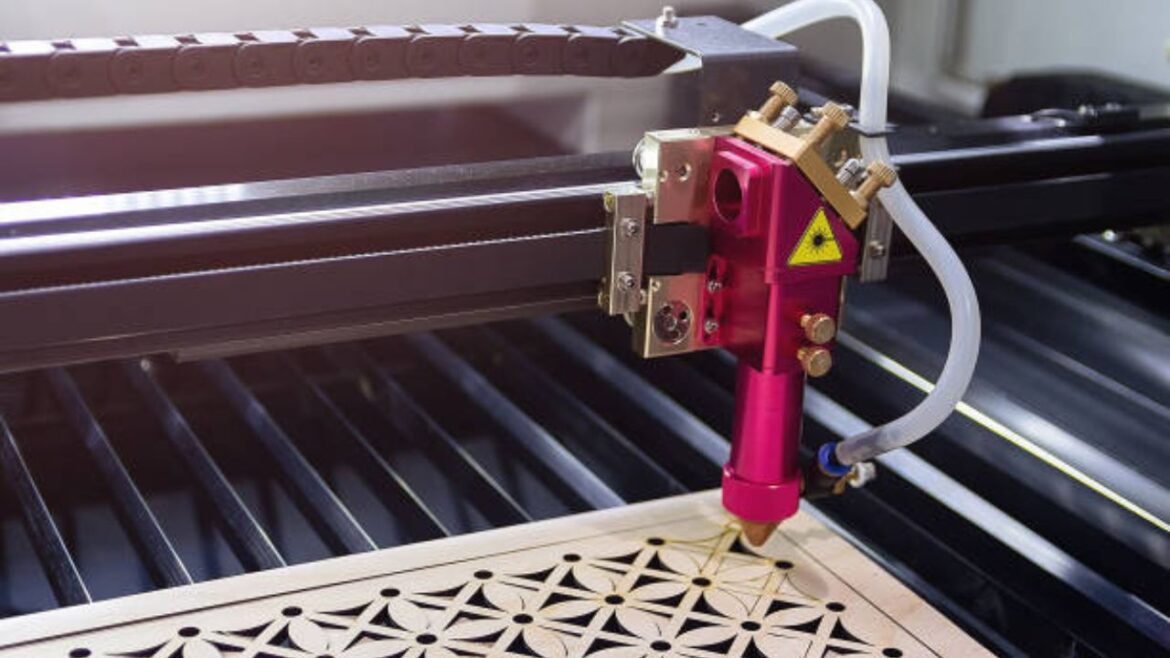

Laser engraving has become one of the most popular technologies for makers, hobbyists, and small businesses. From creating personalized gifts to industrial marking, laser machines allow for precision, speed, and versatility. While many are familiar with CO₂ and diode lasers, there’s another powerful option worth exploring: the IR laser engraver.

So, what makes infrared (IR) laser engraving special? Unlike diode or CO₂ lasers, IR lasers operate at a different wavelength that makes them especially effective for metals, plastics, and reflective surfaces. And with options like the ACMER P2 IR 2W Infrared Laser Engraver now available, even beginners can access professional-level engraving at a low price IR laser engraver point.

In this guide, we’ll explain what an IR laser engraver is, how it works, its benefits, and why it’s considered one of the best budget IR laser engraver solutions in 2024.

What Is an IR Laser Engraver?

An IR laser engraver is a type of laser engraving machine that uses infrared light—usually around 1064nm wavelength—to mark or engrave materials. This wavelength interacts strongly with metals, plastics, and certain non-organic materials where blue diode (450nm) or CO₂ lasers often struggle.

Key Characteristics:

- Wavelength: Around 1064nm (infrared).

- Precision: Ultra-fine spot sizes, often as small as 0.03mm.

- Materials: Metals (copper, brass, aluminum, stainless steel), plastics, acrylic, stone, and glass.

- Functions: Engraving, marking, and even rust removal on metal surfaces.

How Does an IR Laser Engraver Work?

An IR laser engraver diode generates infrared light, which has a stronger interaction with reflective and heat-resistant surfaces. This allows it to:

- Engrave metals directly – Unlike diode lasers that often require coatings or sprays, IR lasers can mark bare metals.

- Work on plastics and acrylics – Creating sharp, high-contrast engravings.

- Remove rust from metals – Restoring tools, knives, or industrial parts.

The fine focus of IR lasers means designs come out crisp, detailed, and professional—even on tough materials.

What Can You Engrave With an IR Laser?

Infrared lasers are known for their versatility across difficult materials. Here’s what you can achieve:

- Metals: Copper, brass, aluminum, stainless steel, gold, silver, titanium.

- Plastics: High-contrast markings for electronics or industrial labeling.

- Acrylic: Clean cuts and engravings for signage or decorative items.

- Stone and rock: Permanent engravings for décor or memorials.

- Glass: Etched designs with sharp contrast.

- Rust removal: Strips away corrosion to restore metal surfaces.

👉 For hobbyists and businesses looking to engrave metal and plastic items, an IR laser is often the best choice.

Spotlight: ACMER P2 IR 2W Infrared Laser Engraver

When searching for a cheap IR laser engraver that still delivers professional performance, the ACMER P2 IR stands out.

Key Features:

- Best budget IR laser engraver in 2024: Affordable yet powerful option for beginners and small businesses.

- Material versatility: Engraves metal, plastic, copper, brass, glass, acrylic, stone, and more.

- Rust removal function: Unique feature that restores metal tools or products.

- Engraving speed: Up to 30,000 mm/min for fast production.

- Precision: Ultra-fine 0.03mm laser spot for detailed designs.

- Ease of use: Pre-assembled module—start working in minutes.

This makes the ACMER P2 IR not only the most low price IR laser engraver in its category but also one of the most versatile solutions available.

Explore more: Best Materials to Laser Cut

IR Laser vs Diode and CO₂ Lasers

When comparing an IR laser engraver diode to other types, here’s how it stacks up:

- Diode lasers excel at wood, leather, and dark acrylic but struggle with bare metals.

- IR lasers engrave metals, plastics, and reflective materials directly.

👉 If you need metal marking, IR wins. For wood projects, diode is still more cost-effective.

- CO₂ lasers are powerful for wood, acrylic, and glass cutting.

- IR lasers are more precise for engraving metals and plastics.

👉 CO₂ is better for cutting, IR is better for metal engraving and fine details.

This is why many workshops combine these technologies for full coverage.

Benefits of Using an IR Laser Engraver

- Metal Engraving – Directly engrave copper, brass, and stainless steel without sprays.

- High Precision – Spot size of 0.03mm for intricate designs.

- Rust Removal – Adds restoration capabilities to your toolset.

- Versatility – Works across metals, plastics, stone, glass, and acrylic.

- Affordability – With machines like the ACMER P2 IR, you can get professional results at a low price IR laser engraver level.

- Fast Production – 30,000 mm/min speed enables both hobby and small business workflows.

Who Should Use an IR Laser Engraver?

- Hobbyists: Perfect for makers who want to engrave jewelry, coins, or small metal projects.

- Small Businesses: Great for custom gifts, industrial tags, and promotional items.

- Workshops: Adds capabilities for restoration (rust removal) and precision marking.

- E-commerce Sellers: Personalize products like tumblers, knives, or accessories to boost sales.

If you’re looking for a cheap IR laser engraver for sale, the ACMER P2 IR offers unmatched value.

Practical Tips for Using an IR Laser Engraver

- Test settings – Different metals and plastics react differently. Start with low power and increase gradually.

- Use safety gear – Always wear protective glasses designed for 1064nm wavelength.

- Prepare surfaces – Clean metal before engraving for best results.

- Ventilation matters – Especially when engraving plastics or removing rust.

- Maintenance – Keep the lens clean and check alignment for consistent precision.

Cost: Is an IR Laser Engraver Worth It?

While industrial fiber lasers can cost thousands of dollars, compact options like the ACMER P2 IR bring IR technology to everyone.

- Cheap IR laser engraver price range: $300–$800.

- Industrial IR or fiber lasers: $1,500–$10,000+.

For beginners and small businesses, the ACMER P2 IR delivers professional performance without breaking the bank, making it the best budget IR laser engraver in 2024.

Future of IR Laser Engraving

The demand for IR lasers is growing as customization trends expand. Expect to see:

- More hybrid machines – Combining diode + IR modules for all-in-one solutions.

- Higher speeds and power – Faster production for business use.

- Wider adoption in jewelry and electronics – Thanks to precision and contrast on metals and plastics.

- Affordable upgrades – With brands like ACMER making IR technology accessible.

FAQs About IR Laser Engravers

Primarily for engraving metals, plastics, stone, glass, and removing rust from metal surfaces.

Yes. The ACMER P2 IR is a low price IR laser engraver that delivers professional results.

It can mark wood, but diodes and CO₂ lasers are better suited for cutting and engraving wood.

You can find them at official brand shops like Acmer Online Shop, as well as other online retailers.

Yes. With its dual capability of engraving multiple materials and removing rust, it’s the best budget IR laser engraver in 2024.

Conclusion

An IR laser engraver is the ultimate tool for anyone who needs precision on metals, plastics, glass, and more. With features like ultra-fine engraving, rust removal, and high speed, IR technology fills the gap where diode and CO₂ lasers fall short.

The ACMER P2 IR 2W Infrared Laser Engraver proves that professional-grade results don’t need to come with a high price tag. As the best budget IR laser engraver in 2024, it brings metal engraving and restoration within reach for hobbyists, workshops, and small businesses alike.

Whether you’re engraving jewelry, customizing tools, or restoring old metal parts, a low price IR laser engraver like ACMER’s makes it possible to produce stunning, profitable results.