Brick Pointing Contractor NYC comes in a variety of styles. Listed below are beaded pointing, flush pointing, and spot pointing. Each style has its benefits and disadvantages. Learn the difference between them for your masonry project. If you’re unsure about which type to choose, consult a professional. Here are some examples of each style:

Beaded pointing

Beaded pointing is a type of masonry joint that gives the structure an elegant appearance. It is suitable for stone, brick and rubble masonry work. Although it is not a permanent solution, it is a cost-effective and quick method of masonry construction. Beaded pointing is difficult to maintain, as it requires a great deal of water. Furthermore, it is more unstable than other types of joints.

Beaded pointing is typically used in historic restorations. This type of pointing involves insertion of a steel rod with a concave shape into the mortar joint. This concave shape makes the joint look better. It also allows water to drain more easily. Beads are also more noticeable, which makes them an appropriate choice for historical restorations. Beaded pointing has become a popular alternative to traditional masonry, but it is also not as strong as brick or stone pointing.

Also Read: How to Choose the Right 2D Game Development Company?

This marks the joints and defines the uniformity of blockwork. The finished product looks more like a brick wall, and is more durable. However, beading is a time-consuming process, and it can be difficult for amateurs.

Beaded pointing is also an alternative method for making masonry joints. This process involves pressing mortar into raked joints, and forming concave grooves using a metal rod with a concave edge. The resulting effect is very appealing, but beaded pointing is vulnerable to damage. You can use either of these methods to point your brickwork. It is important to choose the method that will look best in your project.

Brick Pointing Contractor NYC is a decorative masonry technique. The grooves extend 3mm beyond the face of the joint. This type of pointing also helps preserve the appearance and durability of masonry structures. Moreover, it makes the outside of the structure weatherproof. This type of pointing is a cost-effective option for building projects. However, it requires special expertise and is more time-consuming than other forms of masonry.

Beaded pointing is one of the most popular types of masonry construction. It is an excellent choice for projects with a traditional, rustic feel. Beaded pointing has many advantages. First, it helps in achieving a seamless finish. Secondly, it looks elegant and stylish. Moreover, it ensures the long-term durability of the masonry structure. You will also be able to identify a high-quality finish in your masonry project.

Flush pointing

Flush pointing is a common method of masonry construction. Instead of using a steel rod and trowel, this method uses a V-shaped tool to insert the pointing mortar into the joint and press it into place. The finished product looks smooth, and is more durable than traditional pointing methods. It also resists the provision of space in the masonry joint, and gives a better appearance.

Flat pointing is similar to keyed pointing, with a few minor differences. This method improves the appearance of the joint and prevents rainwater from collecting in a V-shaped recess.

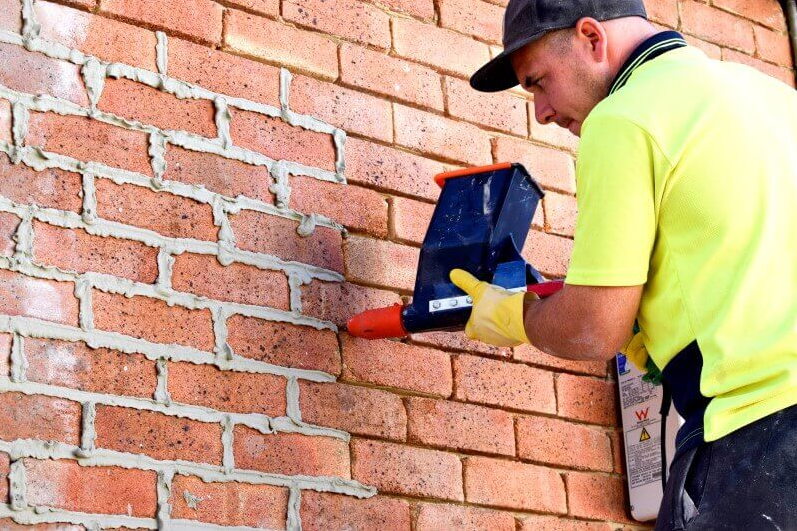

The first step in flush pointing is cleaning the joint’s surface with a brush or other cleaning agent. The second step is pressing the mortar into the joint. Afterwards, trim the edges of the pointing with a straight edge.

Flush pointing in Masonry construction is a common method of joining masonry joints. It is best to apply the mortar at a depth of 20 mm when it is soft, and use a small spatula to apply it.

Brick Pointing Contractor NYC is more durable than weathered pointing, which involves pressing mortar into the joint and pushing the top of the joint back. Its smooth finish gives the masonry a more uniform appearance, and it’s durable, too. It prevents debris from accumulating in the joints. The most common type of pointing is flush pointing, but there are other types of masonry pointing.

Tuck pointing is another common technique. This technique fills the joint in between rakes. It requires a small rectangular groove at the center of the joint. The width of this groove is about 5 mm. Beaded pointing is similar to tuck pointing. Both methods have advantages and disadvantages.

Spot pointing

There are several different types of pointing. This method involves pressing mortar into a joint and keeping the face of the pointing vertical during placement. Another type of pointing is spot pointing.

Brick Pointing Contractors Near Me involves pressing mortar into joints with a V-shaped tool. It is a decorative pointing technique that results in a nice appearance. Keyed pointing is more costly than spot pointing. It requires more work but gives the most beautiful appearance. This technique is the most popular form of brick masonry pointing. In masonry construction, however, there are many types of pointing methods.

Brick Pointing Contractor NYC is the most basic type of pointing. It is durable and requires the filling of a raked joint with mortar. It is important to choose the right repointing mortar to ensure the best results. For more complex projects, you can use a tuck-pointing method.

This process is more difficult than spot pointing, but it is effective for repairing brickwork walls and filling voids between joints. It is also an excellent option for structures that experience low rainfall. Regardless of the type of pointing technique you choose, it is essential to use personal protective equipment to minimize the risks associated with fine dust particles. It is vital to use the correct hammer and chisel to apply the mortar.

Brick Pointing Contractor NYC is an excellent option for small-scale masonry projects. It can help prevent the need for a solid tuckpointing job. If the spot pointing process fails, you can use a patchwork technique to restore the damaged area. Spot pointing is also a good option if the rest of the wall is intact and not damaged. The cost savings are worth the effort. You can save yourself from the expense of solid tuckpointing by using spot pointing instead.