Through hole PCB assembly is a process that uses the soldering technique of through holes. This process provides a high degree of flexibility and can withstand excessive environmental stresses. However, it can be expensive and requires considerable skill to perform. In this article, we’ll look at the characteristics of a through-hole PCB assembly and how to get it done properly.

Process

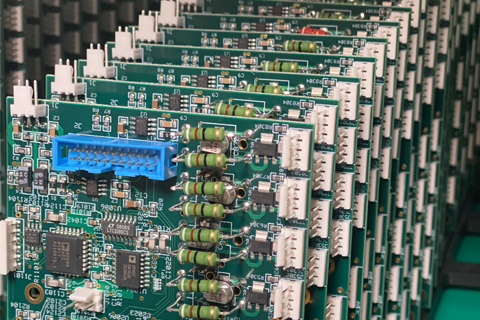

If you are looking to manufacture PCBs in bulk quantities, then the Through Hole PCB Assembly process is your best bet. It eliminates the chances of open circuits or short circuits and is a great choice for mounting bulkier or heavier components. This method is also stronger than other PCB assembly methods, as it is virtually impossible to pull components out once they are in place.

In a nutshell, the through-hole PCB assembly process involves the soldering of a small number of circuit boards. This method is often used to create prototypes, and is an industry standard. This technique provides high reliability and high power handling capability and is ideal for high-voltage and current components. It is also ideal for use in the military and aerospace sectors.

Characteristics

Through hole PCB assembly is a process of constructing circuit boards with through holes, rather than holes cut into the PCB. The difference between through hole and surface mount PCB assembly is primarily in the way that the parts are installed. Standard thru-hole components, such as resistors and capacitors, will be soldered into plated through-holes. Other parts, including connector legs, press-fit parts, and guide pins, will be installed into non-plated through-holes.

Through-hole PCB assembly is popular for prototyping boards, which require quick assembly for proof-of-concept evaluation. However, through-hole mounting limits the routing space for multilayer PCBs because through-hole component leads must go through all layers of the board. Also, it reduces the manufacturing efficiency, as through-hole components must be hand soldered.

Cost

The cost of through hole PCB assembly varies greatly depending on many factors, including the labour cost, the stencil used and turnaround time. In addition, the quantity of assembled boards and packaging used will affect the overall cost. Many companies charge an additional fee for programming, though Bittele does not.

PCBs are a very complex product, with many layers and thousands of components. Therefore, it is important to understand the processes involved in PCB manufacturing, including material selection. This will influence the durability and performance of the board. During the manufacturing process, the packaging of the PCB is critical. Different electronic components require different packaging methods and will require more time and labor.

Durability

Through-Hole assembly is a popular method for the manufacturing of electronic circuit boards. This method requires precision soldering and a tight grasp of the components. This method helps manufacturers avoid the risks of a faulty board and ensures durability of their products. However, there are some disadvantages that may hinder the success of a through-hole PCB assembly.

When choosing through-hole PCB assembly, it is important to choose components that are designed to resist abrasion. For example, a PCB containing many small parts must be durable. Through-hole components should be modeled in CAD systems using the latest data sheets. Also, keepout zones and clearances must be considered.

Rules for soldering

Soldering through hole PCB assemblies requires adhering to a set of rules to ensure that the solder flows correctly. These rules include maintaining a minimum clearance between the hole and conductive pads, and ensuring that the leads are at least half the length of the component. The minimum length of the leads must not exceed two lead diameters, and they must be bent to ensure that the solder mask is not covered by the component. It is also important to ensure that the components are not positioned in such a way that they obscure the solder mask. In some cases, soldering through a hole may require soldering on both sides, which can increase the soldering time.

When soldering through a hole, the soldering iron must be clean before proceeding. Traditionally, wet sponges were used to clean the soldering iron, but this practice may sully the tip of the iron. The proper way to clean the soldering iron is by using a flux pen. Flux is an organic agent added to lead-free solder. Applying liquid flux is helpful because it makes solder joins look better and can help reduce the risk of oxidation on the PCB and through hole components.